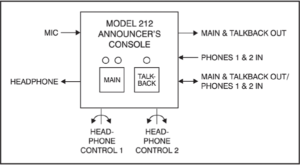

Whether it's microphone preamplification, switching of main and talkback audio signals, or the headphone output, superior audio quality is maintained throughout. A microprocessor provides the Model 212's logic power, allowing precise control of the unit's operation. A range of choices allows the desired operating configuration to be easily selected. While flexible, the user is presented with an easy-to-use set of controls and indicators. The digital audio interfaces are directly compatible with system environments that use AES digital audio signals as their preferred transmission method. Unbalanced, 75 ohm interfaces (AES3id) are standard with balanced 110 ohm (AES3) support also available.

While "all-digital" audio installations are getting closer and closer to reality, analog signals continue to play a role and will probably do so for many years. As such, the Model 212 also offers support for analog audio inputs, main output and talkback outputs functions. While requiring the installation of optional connectors or modules, these analog resources can help complete specialized applications.

A truly next-generation product, extensive research into the needs and desires of field production personnel was integral to the Model 212's creation. While primarily targeted for on-air television applications, specialized features are included to allow the Model 212 to be used in a variety of other audio applications. These include on-air radio broadcasting, stadium announcement, live production, and voice-over/narration booths.

Microphone Input

A high-performance microphone pre-amplifier circuit provides low-noise/low-distortion amplification over a 10 to 50 dB gain range. The gain is adjustable in 10 dB steps. The input is compatible with balanced dynamic or condenser microphones. The microphone power source is 48 V nominal and meets the worldwide P48 phantom standard. An LED indicator serves as an aid for optimizing the setting of the preamplifier's gain. The output of the microphone preamplifier is routed to the compressor circuit that supports the main and talkback audio channels.

Dynamic Range Control

A studio-quality compressor circuit is provided to control the dynamic range of the analog signal coming from the microphone preamplifier. Far from a simple "clipper," the circuit utilizes a sophisticated laser-trimmed voltage-controlled-amplifier (VCA) integrated circuit for quiet, low-distortion level control. The output of the compressor is used by the main and talkback channels, being routed to the inputs of their respective analog-to-digital converter circuits. The threshold of the compressor can be configured from among two values. With the compressor configured to –14 dBFS some dynamic range control would be expected during normal operation. While possibly inappropriate for major on-air situations, having dynamic range control of the signal can offer increased performance for many applications. This would be appropriate for applications such as stadium announcement positions, sports events using nonprofessional on-air talent, as well as situations where the risk of digital "clipping" is present. When configured for –4 dBFS, dynamic range control will only take place as the signal approaches the level limit of the digital signal. During normal operation the compressor would not be active.

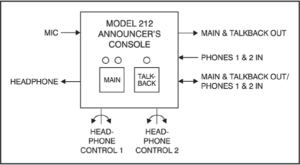

Main and Talkback Audio Channels

Internally, the Model 212 creates analog main and talkback audio channels. The main audio channel is designed to serve as the on-air, stadium announcement, or other primary audio feed. The talkback audio channel is intended to provide production trucks, control rooms, or support personnel with a talent-originated cue signal. The two analog channels are converted to 24-bit PCM digital audio and multiplexed and formatted into an AES digital audio "stream." The A/D converters and digital transmitter circuitry is synchronized ("locked") to the selected digital input signal. If that signal Is not present the Model 212 will automatically revert to an internal clock which provides a 48 kHz sampling rate. The main audio channel is assigned to digital channel 1 with talkback audio assigned to digital channel 2. The composite digital audio signal is routed to two physical interfaces. One output is AES3id compliant (unbalanced, 75 ohms) with a BNC connector for interfacing. This professional interface is transformer-coupled and capable of driving long broadcast cable runs.

The digital audio output signal is also routed to a unique bidirectional digital interface. Similar to AES3id, it uses a BNC connector and supports two channels of audio in each direction over a single 75 ohm cable. The bidirectional audio interface will find use in specialized applications, including direct integration with panel ports on Riedel® intercom systems.

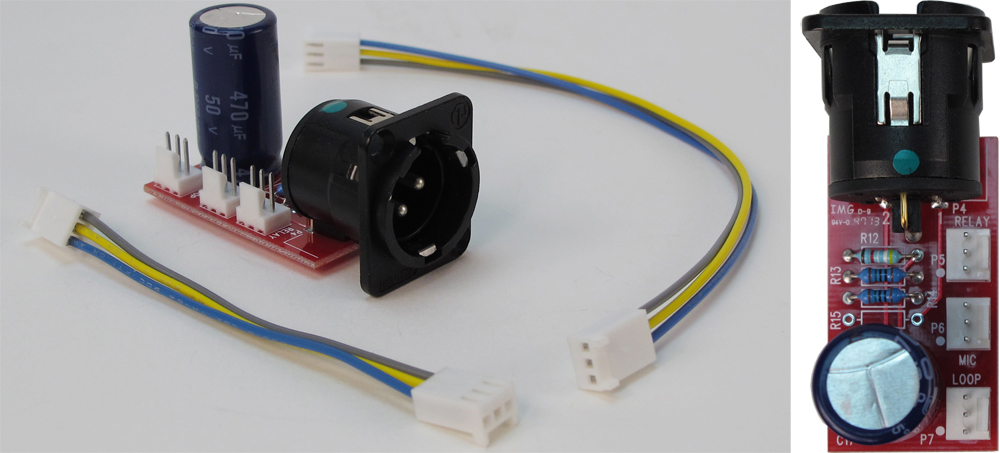

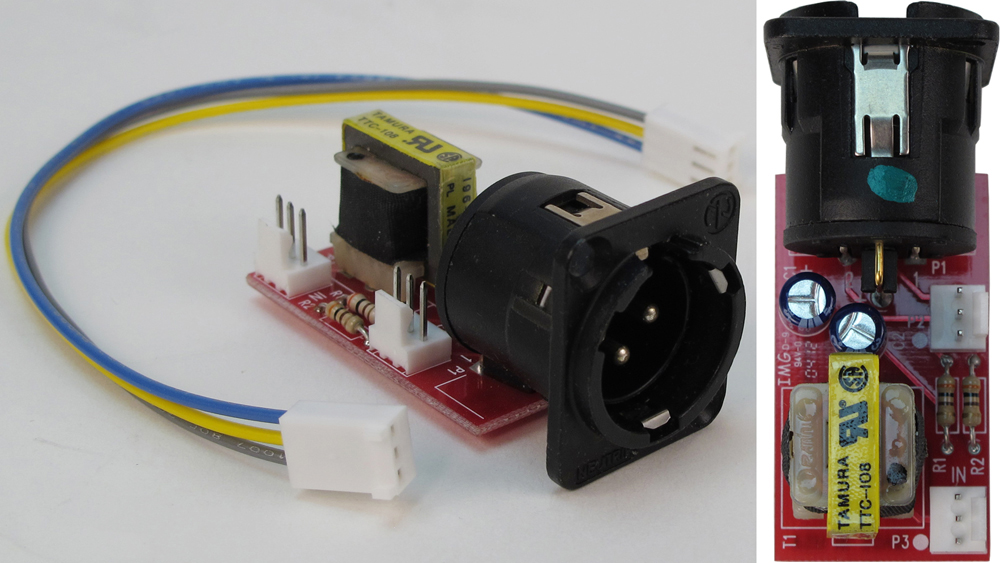

For enhanced flexibility, the Model 212 includes the resources to support a third digital output. Circuitry, located on the printed circuit board assembly, creates an AES3 compliant, 110 ohm nominal, transformer-balanced digital output. Gaining access to this output simply requires adding a 3-pin male XLR connector to one of the two spare connector locations on the Model 212's back panel. Connector kits, available from Studio Technologies, make this a simple task.

The Model 212 isn't limited for use in "on-air" applications. A special feature can be enabled, placing the unit in a "production" mode. When this mode is active enabling the talkback audio channel will no longer force the main audio channel to mute. This allows the main audio channel to be used as a second talkback output. In this configuration the unit can be even more powerful when used in a live event application, such as serving as a master console for a production director.

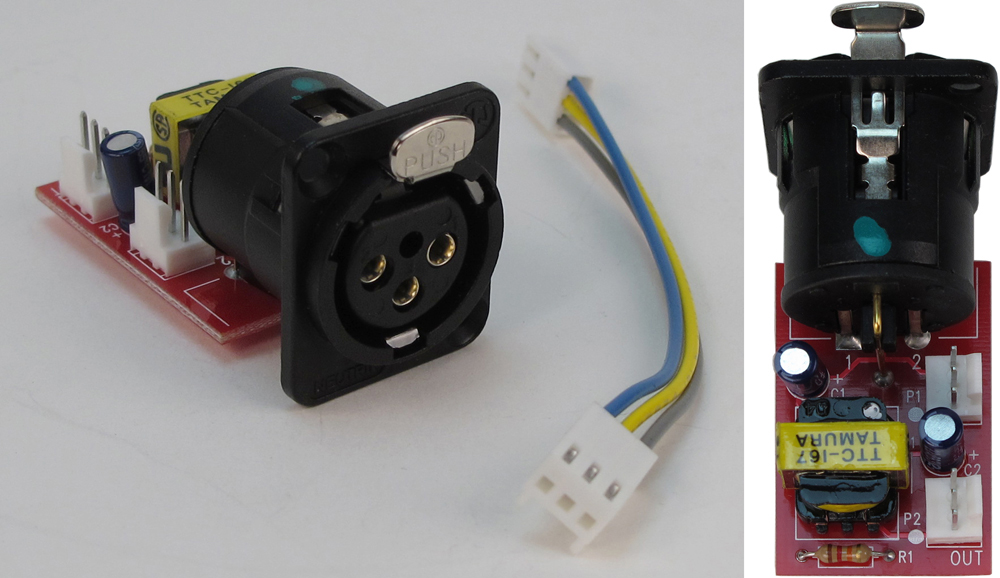

By installing optional connectors or modules analog line-level versions of the main and talkback output signals are available. These "click-free" outputs can be useful in applications where both digital and analog signals are required.

User Controls and Status Indicators

Two pushbutton switches, three LED indicators, and two rotary controls provide the user with a clear, easy-to-use interface. One pushbutton switch controls the status of the main audio channel. This is the audio signal intended for on-air, announcement, or other primary uses. Two LEDs display the on/off status of the main audio channel. A second pushbutton switch controls the status of the talkback audio channel. This is the audio signal used to communicate with producers, directors, spotters, or other behind-the-scenes production personnel. A status LED is associated with the talkback button. Two rotary controls allow the user to adjust the level of the stereo headphone output.

Operational Flexibility

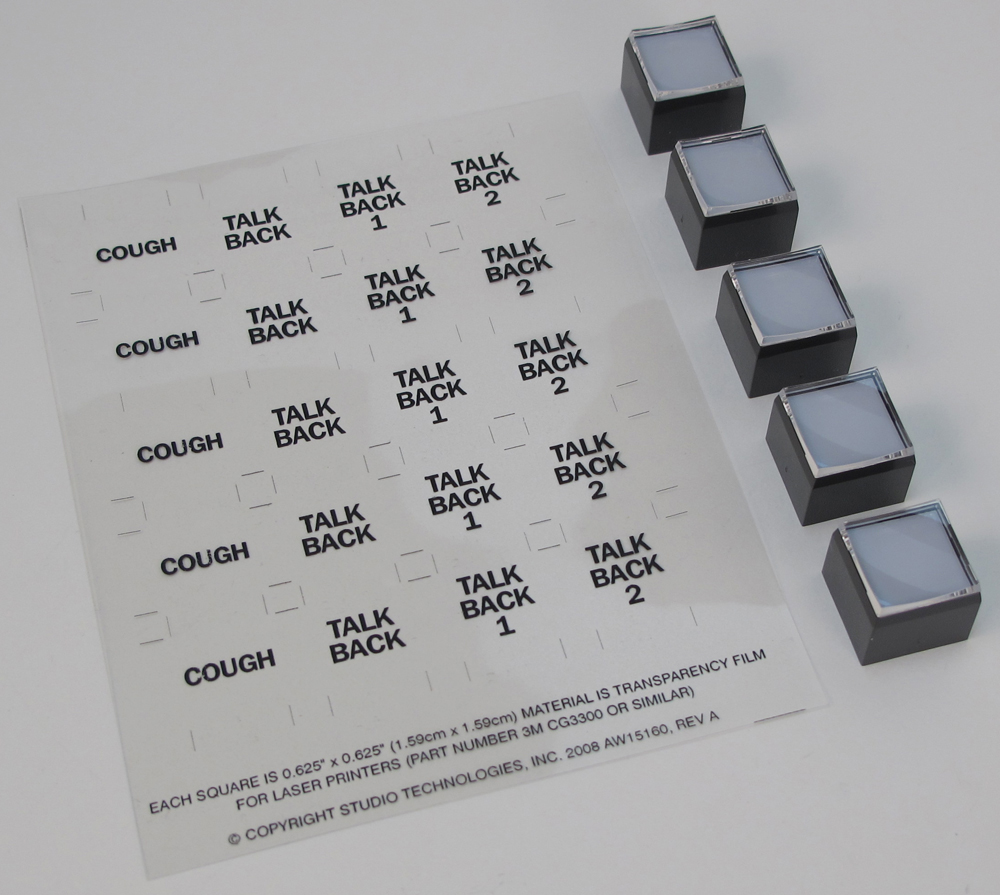

Much of the Model 212's unique capabilities derive from the ability to configure the on/off control of the main and talkback audio channels. To meet the needs of the many specific broadcast and production applications, a variety of button operating modes are available. The main button, located on the left side of the front panel, can be selected to operate from among four modes. In the "push-to-mute" mode the button performs a momentary mute of the main audio channel. In this way a "cough" button function is created, something typically required for television sports broadcasting. In the "push-to-talk" mode the button provides a momentary active function for the main audio channel. This mode would be appropriate for applications such as stadium announcement. An alternate action "latching" configuration allows the button to enable or disable the main audio channel as desired. This is useful in radio broadcasting, announce-booth, or voice-over applications. The fourth mode provides a hybrid function, supporting both push-to-talk and tap-to-enable/tap-to-disable operation. This operation is similar to that found in many broadcast intercom system user stations.

The button associated with the talkback function can be configured to operate from either of two modes. One of the modes supports a "push-to-talk" function. This is typically used for on-air broadcast applications. The other mode provides a hybrid function, the operation of which is discussed in the previous paragraph. The hybrid mode is especially useful when the Model 212 is used in a production-support application. Headphone Output

Two rotary controls are provided for user adjustment of the headphone output levels. For application flexibility the actual function of the two "pots" is configurable. For traditional on-air sports applications they can be selected to the dual-channel ("level/level") mode which provides independent control of the left- and right-channel volume. For use with dual-channel cue signals, or to support user preference, the stereo ("level/balance") mode can be selected. In this mode one control adjusts the overall level of both the left and right channels, while the other allows adjustment of the left/right level balance. To help minimize the chance of broadcast cues being missed, both level control modes can be configured so that a minimum headphone output level is maintained. Alternately, the headphone output can be set to fully mute when the controls are at their minimum position. The rotary controls can also be set for a reverse left/right mode. This is provided for cases where a user needs to wear their headset "reversed" to support alternate camera angles. By using this special mode intuitive operation will be maintained and a comfortable work environment assured.

Provision has been made to support applications where a monaural cue feed is desired. A configuration switch allows the summing (combining) of the selected left and right headphone sources. In addition to creating a dual-channel mono output it also allows the level controls to be configured as a simple 2-channel mixer.

The stereo headphone output was designed to meet the needs of contemporary headphones and headsets. Specifically, the output circuits act as voltage, rather than power, drivers. In this configuration they can provide high output levels with very low distortion and noise, along with minimal current consumption. The output circuits are configured to safely drive stereo or mono loads. This ensures that all types of headphones, headsets, and earpieces can be directly connected.

Audio Quality and Protection

The Model 212's circuitry was carefully tailored to provide excellent audio performance. Professional-quality components are featured throughout. For reliability all audio routing is performed using solid-state devices. In all critical audio paths, "clickless" performance is provided. All audio inputs and outputs make extensive use of protection components. This limits the chance of damage from ESD and other undesirable, yet real-world, hazards.

Power Sources

The Model 212 requires an external source of nominal 24 Vdc, 150 mA maximum, for operation. Inside the Model 212, an internal switch-mode power supply creates the various voltage "rails" required by the internal circuitry. An external power supply is included with each unit.

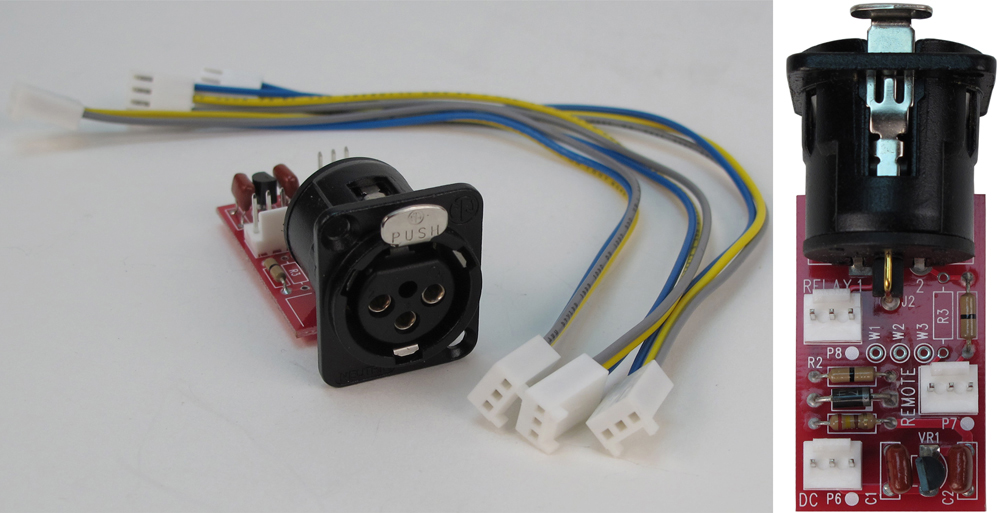

Relay Contacts

Model 212 resources include a general-purpose relay, allowing specialized configurations to be created using its two form-C (DPDT) contacts. Under software control, the relay can be configured to follow the state of the main and talkback audio channels. Taking advantage of the back-panel locations provided for additional XLR connectors, a technician may easily implement a variety of functions such as providing an "on-air" indicator or performing loudspeaker muting during talkback.

Configuration

Model 212 configurations are made using a number of DIP switches. One 8-position switch assembly is used to set the gain of the microphone preamplifier, the on/off status of phantom power, the compressor threshold, and the headphone stereo/mono mode. Another 8-position switch assembly configures which of the audio sources is routed to the headphone output. A 12-position switch assembly communicates the desired operating modes to the microprocessor. All switches are accessible via the bottom of the Model 212's enclosure; the unit does not have to be disassembled. Changes made to any of the configuration parameters become active immediately. To prevent access to the configuration switches a security plate included with each unit, is attached to the bottom of the enclosure.

Connectors

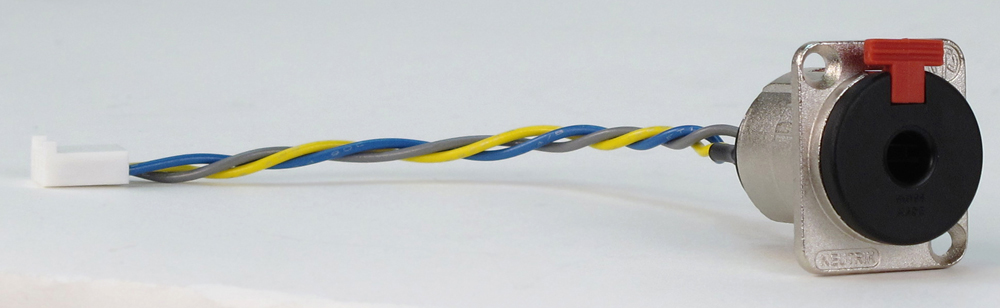

The Model 220 uses standard connectors throughout. The microphone, IFB, and line inputs use 3-pin female XLR connectors. The main and talkback outputs use 3-pin male XLRs. The headphone output utilizes a ¼-inch 3-conductor jack. The external source of 24 Vdc power is connected by way of a 2.1 x 5.5 mm "locking" coaxial power jack.

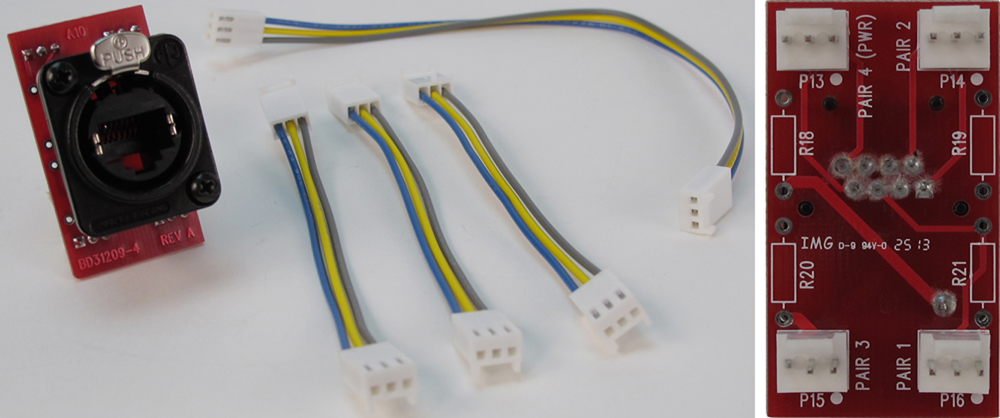

Additional Connector Locations

The Model 212 uses standard connectors throughout. The microphone input uses a 3-pin female XLR connector. The digital audio inputs and outputs use BNC connectors. A ¼-inch 3-conductor jack is used for the headphone output. The external source of 24 Vdc power is connected by way of a 2.1 x 5.5 mm "locking" coaxial power jack.

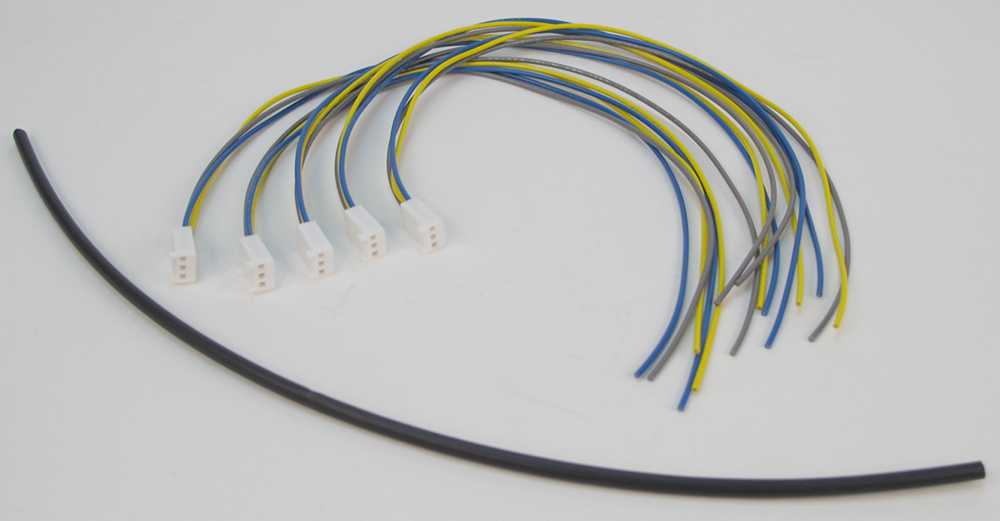

In the world of broadcast and production audio it's fair to say that applications vary widely. To this end, one or two additional XLR connectors can easily be mounted into the Model 212's back panel. Multiple 3-position "headers" located on the Model 212's circuit board provide technician-access to all input and output connections. Using a factory-available interface cable kit allows a Model 212 to be optimized to meet the exact needs of specific applications. For example, some applications may prefer to use a multi-pin XLR connector to interface with a headset. This can easily be accomplished by adding the appropriate 5-, 6-, or 7-pin XLR connector and making a few simple connections. Other applications may benefit from having "mult" or "loop-through" connections, something easily incorporated into a Model 212. One or two optional line input cards, as previously discussed, can also be mounted in the spare XLR positions. Line output cards are available to support the analog line-level main and talkback outputs.